ABOUT US

Optical Perspectives Group

Curricula Vitae, Qualifications & Accomplishments

At Williams College, Bob was a student of Profs. Fielding Brown and David Park. It was Prof. Brown who started Bob’s career in optics when he asked, “….if he could align the end mirrors of a laser cavity with an autocollimator”? Bob assured him “Yes”, and he replied, “Great. Show up tomorrow at 9 and we’ll get started”. Little did Bob realize that the research Prof. Brown envisioned, to see if one could produce second harmonic light in reflection from a metallic surface, would lead to a topic still current today.

Along with under-graduate co-author Arthur Sleeper, their paper “Nonlinear Optical Reflection from a Metallic Boundary”, Phys. Rev. Lett., 14, 1029-31 (1965) is being cited today by researchers doing investigations of the interaction of photons and electrons at surface boundaries. Prof. Park was instrumental in helping Bob with the theoretical aspects of this weak interaction that produced about 1 second harmonic photon for every 1015 incident fundamental wavelength photons.

Bob Parks’ Experience

1967

Eastman Kodak Company; Optical Engineer

On his very first job assignment, Bob had to use an autostigmatic microscope (ASM) to measure the radius of curvature of long radius test plates. At the time, he had no idea what he was using, how it worked, or that his whole career would be tied to variations of this test device.

Later, Bob and his office mate, Don Oinen, were the first people in the Research and Engineering Division to ask for, and get, a programmable calculator in their office so they did not have to submit all their simpler optical design calculations to the mainframe computer to get answers.

1969

ITEK Corp.; Optical Test Engineer

The six multi-color S-190 cameras for Space Lab were adjusted for magnification and focus by Bob and his technician, Bob Sherlock. The 150 mm efl cameras with 70 mm film format had to be tuned so that the film from the cameras could be overlaid with less than +/- 2 micron image misalignment at the edges of the field even though the cameras operated in different spectral bands. This work was the genesis of the idea for attaching an electronic sensor, in this case a quad cell, in place of an eyepiece on an ASM because 2 of the cameras were used in the infrared and the light source was not visible to the eye.

Bob also started doing modal analysis of optical test wavefront errors by using Zernike polynomials to represent the wavefront errors. By quantitatively separating the wavefront errors into specific aberrations it made particular errors in the alignment of optical tests more obvious.

1972

Frank Cooke, INC., Hands On Optical Fabrication Experience

In order to better understand how to tolerance optical drawings Bob joined Frank Cooke at his optical shop in order to learn from a master how optics were made and learn of the tools available to the optician in working his or her craft. One thing that was immediately obvious at Cooke’s shop was that women were at least as good as men, if not better, as opticians.

One of the products Frank specialized in was hyper hemispheric glass domes. The inner and outer surfaces had to be concentric and the decenter had to be measured. Ray Boyd, the head metrologist, made a custom ASM by assembling a fiber preform that had been drawn into a small tip and bent down into the eyepiece of a microscope body. By shining a bright light on the exposed end of the preform, the microscope focused a bright spot at the centers of curvature of the surfaces of the dome. Spots reflected from the two surfaces were visible in the eyepiece and their separation laterally and in focus gave the decenter of the surfaces in 3 degrees of freedom. The simplicity of the technique and instrument made a lasting impression on Bob.

1976

Optical Sciences Center at the Univ. of Arizona; Optical Shop Manager

Through networking connections with Jim Wyant and Bob Fischer whom Bob knew from Itek, and the training he got at Frank Cooke’s shop, he was a perfect match for the opening at the College of Optical Sciences to manage the optical shop. One of his first tasks was to develop an algorithm to separate the errors in test optics from the errors in the mirror being tested by doing a rotational shear. This became the basis for further work by others in the area of absolute testing.

Another accomplishment was the specification and installation of a 6 m swing CNC precision grinder for contouring large aspheric mirror blanks. Even though the machine only had 32K of memory, Bob with the help of Bill Kuhn and Cary Kittrell, got the machine to do 3 dimensional contouring precise to the limits of the machine control.

The idea of an autostigmatic microscope (ASM) was advanced during this time making use of a commercially available eyepiece from EG&G with a fiber optic probe in the center of the field to act as the point source. The ASM proved a very useful optical test and alignment tool until the eyepiece went out of production and there was no replacement on the market.

1989

Optical Fabrication and Testing Consulting, Allen Board of Investigation for the Hubble Telescope

Bob worked for the Allen Board of Investigation and spent extended periods at Hughes Danbury gathering background material for the Board. With the help of employees at Hughes Danbury, he located the apparent cause of the error, and helped write and edit the Allen Board report.

For his effort Bob received a NASA Public Service Medal in 1991.

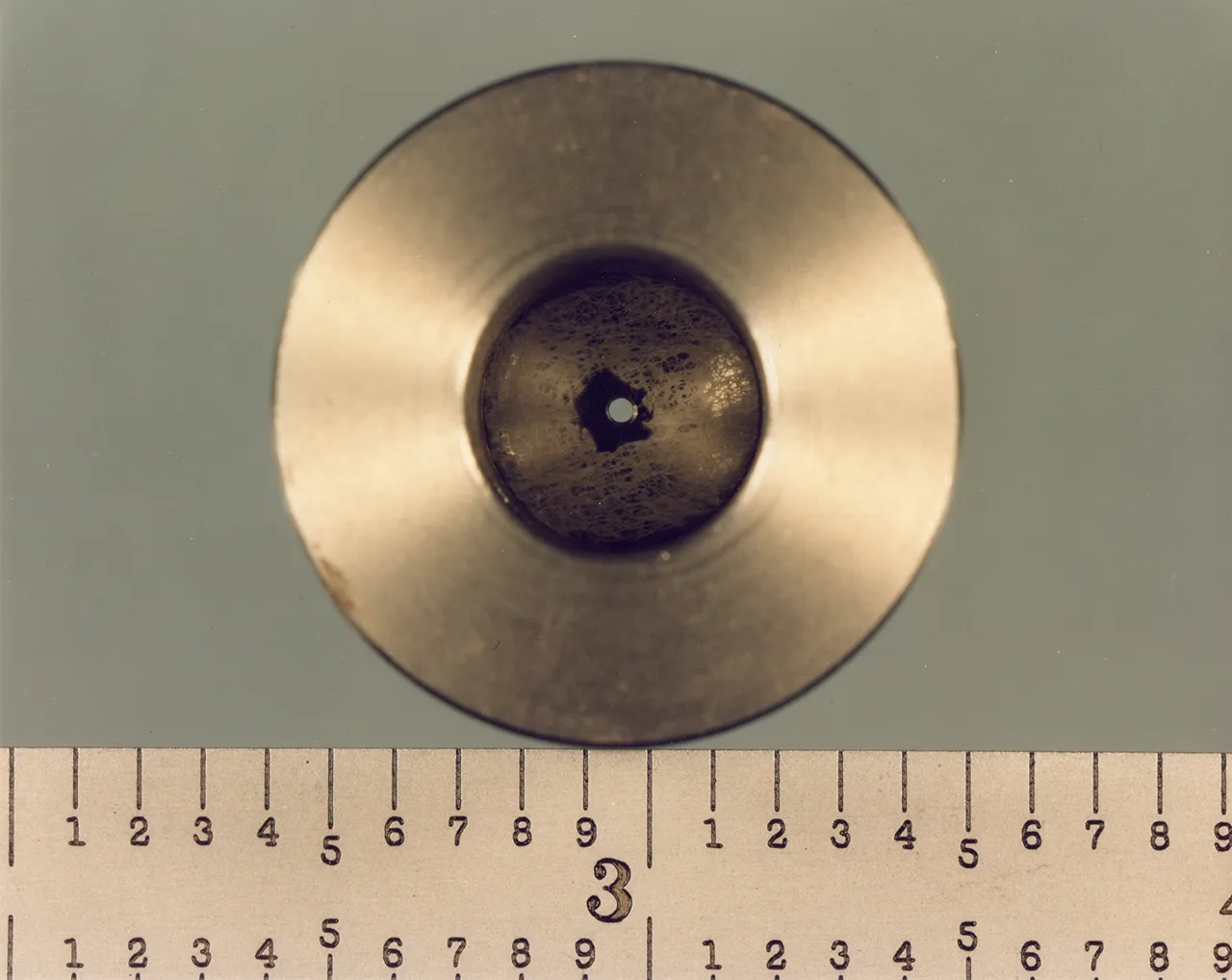

These are color photos from the report.

MORE INFO: The Hubble Space Telescope Optical Systems Failure Report

1992

Formed Optical Perspectives Group, LLC (OPG) with Bill Kuhn

One of the earlier consulting contracts that OPG got was from a local company, ETEC, building a laser scanner for printing PCB’s. The design included several toric lenses with rectangular outlines along with spherical lenses and mirrors whose centers of curvature had to be precisely aligned to the scanner’s optical axis. OPG built and patented (US Patent 6,924,897) an ASM that had an analog CCD camera and a Shack cube to produce a reference point for alignment.

The whole device was about 60x60x22 mm in size and easily attached to the ram of a coordinate measuring machine (CMM). Using the CMM as a large x-y-z stage it was easy to align all the optics to a common axis in a couple of hours rather than the weeks it had been taking using the touch probe on the CMM. Furthermore, the optical performance of the assembled lens was better than the prior assembly method.

Although the ASM worked well and the customer was very pleased with it, an obvious flaw was seen in the design. Once the reflected spot of light was overlapped with the reference spot the alignment could not be made better; one spot obscured the other. At the same time, Bill realized that with a digital camera and compatible software the reference spot could be created electronically and the reflected spot made to coincide with the reference to less than a micron by centroiding on the reflected spot. This was the basis of what is now sold as the PSM, the design of which was almost all Bill’s.

The first couple of PSM’s were purchased by the Breault Research Organization for the alignment of an off-axis two mirror telescope and by Raytheon Missiles Systems by an engineer who had worked at ETEC and realized how the PSM would aid in the alignment of some of the optics at Raytheon.

FURTHER IDEAS OF HOW THE PSM CAN BE USED FOR ALIGNMENT AND TEST ARE SHOWN IN THE TECHNICAL LIBRARY SECTION OF THE WEB SITE, IN PSM APPLICATION NOTES.

1967

Eastman Kodak Company; Optical Engineer

On his very first job assignment, Bob had to use an autostigmatic microscope (ASM) to measure the radius of curvature of long radius test plates. At the time, he had no idea what he was using, how it worked, or that his whole career would be tied to variations of this test device.

Later, Bob and his office mate, Don Oinen, were the first people in the Research and Engineering Division to ask for, and get, a programmable calculator in their office so they did not have to submit all their simpler optical design calculations to the mainframe computer to get answers.

1969

ITEK Corp.; Optical Test Engineer

The six multi-color S-190 cameras for Space Lab were adjusted for magnification and focus by Bob and his technician, Bob Sherlock. The 150 mm efl cameras with 70 mm film format had to be tuned so that the film from the cameras could be overlaid with less than +/- 2 micron image misalignment at the edges of the field even though the cameras operated in different spectral bands. This work was the genesis of the idea for attaching an electronic sensor, in this case a quad cell, in place of an eyepiece on an ASM because 2 of the cameras were used in the infrared and the light source was not visible to the eye.

Bob also started doing modal analysis of optical test wavefront errors by using Zernike polynomials to represent the wavefront errors. By quantitatively separating the wavefront errors into specific aberrations it made particular errors in the alignment of optical tests more obvious.

1972

Frank Cooke, INC., Hands On Optical Fabrication Experience

In order to better understand how to tolerance optical drawings Bob joined Frank Cooke at his optical shop in order to learn from a master how optics were made and learn of the tools available to the optician in working his or her craft. One thing that was immediately obvious at Cooke’s shop was that women were at least as good as men, if not better, as opticians.

One of the products Frank specialized in was hyper hemispheric glass domes. The inner and outer surfaces had to be concentric and the decenter had to be measured. Ray Boyd, the head metrologist, made a custom ASM by assembling a fiber preform that had been drawn into a small tip and bent down into the eyepiece of a microscope body. By shining a bright light on the exposed end of the preform, the microscope focused a bright spot at the centers of curvature of the surfaces of the dome. Spots reflected from the two surfaces were visible in the eyepiece and their separation laterally and in focus gave the decenter of the surfaces in 3 degrees of freedom. The simplicity of the technique and instrument made a lasting impression on Bob.

1976

Optical Sciences Center at the Univ. of Arizona; Optical Shop Manager

Through networking connections with Jim Wyant and Bob Fischer whom Bob knew from Itek, and the training he got at Frank Cooke’s shop, he was a perfect match for the opening at the College of Optical Sciences to manage the optical shop. One of his first tasks was to develop an algorithm to separate the errors in test optics from the errors in the mirror being tested by doing a rotational shear. This became the basis for further work by others in the area of absolute testing.

Another accomplishment was the specification and installation of a 6 m swing CNC precision grinder for contouring large aspheric mirror blanks. Even though the machine only had 32K of memory, Bob with the help of Bill Kuhn and Cary Kittrell, got the machine to do 3 dimensional contouring precise to the limits of the machine control.

The idea of an autostigmatic microscope (ASM) was advanced during this time making use of a commercially available eyepiece from EG&G with a fiber optic probe in the center of the field to act as the point source. The ASM proved a very useful optical test and alignment tool until the eyepiece went out of production and there was no replacement on the market.

1989

Optical Fabrication and Testing Consulting, Allen Board of Investigation for the Hubble Telescope

Bob worked for the Allen Board of Investigation and spent extended periods at Hughes Danbury gathering background material for the Board. With the help of employees at Hughes Danbury, he located the apparent cause of the error, and helped write and edit the Allen Board report.

For his effort Bob received a NASA Public Service Medal in 1991.

These are color photos from the report.

MORE INFO: The Hubble Space Telescope Optical Systems Failure Report

1992

Formed Optical Perspectives Group, LLC (OPG) with Bill Kuhn

One of the earlier consulting contracts that OPG got was from a local company, ETEC, building a laser scanner for printing PCB’s. The design included several toric lenses with rectangular outlines along with spherical lenses and mirrors whose centers of curvature had to be precisely aligned to the scanner’s optical axis. OPG built and patented (US Patent 6,924,897) an ASM that had an analog CCD camera and a Shack cube to produce a reference point for alignment.

The whole device was about 60x60x22 mm in size and easily attached to the ram of a coordinate measuring machine (CMM). Using the CMM as a large x-y-z stage it was easy to align all the optics to a common axis in a couple of hours rather than the weeks it had been taking using the touch probe on the CMM. Furthermore, the optical performance of the assembled lens was better than the prior assembly method.

Although the ASM worked well and the customer was very pleased with it, an obvious flaw was seen in the design. Once the reflected spot of light was overlapped with the reference spot the alignment could not be made better; one spot obscured the other. At the same time, Bill realized that with a digital camera and compatible software the reference spot could be created electronically and the reflected spot made to coincide with the reference to less than a micron by centroiding on the reflected spot. This was the basis of what is now sold as the PSM, the design of which was almost all Bill’s.

The first couple of PSM’s were purchased by the Breault Research Organization for the alignment of an off-axis two mirror telescope and by Raytheon Missiles Systems by an engineer who had worked at ETEC and realized how the PSM would aid in the alignment of some of the optics at Raytheon.

FURTHER IDEAS OF HOW THE PSM CAN BE USED FOR ALIGNMENT AND TEST ARE SHOWN IN THE TECHNICAL LIBRARY SECTION OF THE WEB SITE, IN PSM APPLICATION NOTES.

The Point Source Microscope (PSM)

A complete, self-contained, portable metrology system.

To learn more about the PSM’s unique features and the origin of the PSM click here.

Let’s have a talk together

USA

Innovations Foresight

4432 Mallard Point,

Columbus, IN 47201 USA

Telephone:

1-215-884-1101

Contact:

Customerservice@

All Asian Countries Except China

清 原 耕 輔 Kosuke Kiyohara

清原光学 営業部 Kiyohara Optics / Sales

+81-3-5918-8501

opg-sales@koptic.co.jp

Kiyohara Optics Inc.

3-28-10 Funado Itabashi-Ku Tokyo, Japan 174-0041

China

Langxin (Suzhou) Precision Optics Co., Ltd

1st floor, Building 10, Yisu Science and Technology Innovation Park, 100 meters west of the intersection of Xinhua Road and Weimeng Road, Kunshan City, Suzhou City, Jiangsu Province, 215345

Telephone: +860512-57284008

Contact: Wang Zengkun

+8617090133615

wangzengkun@langxinoptics.com

Copyright ©

Website by CS Design Studios

Headquarters: 7011 E Calle Tolosa, Tucson, AZ 85750

Laboratory: 1661 S Research Loop, Tucson, AZ 85710